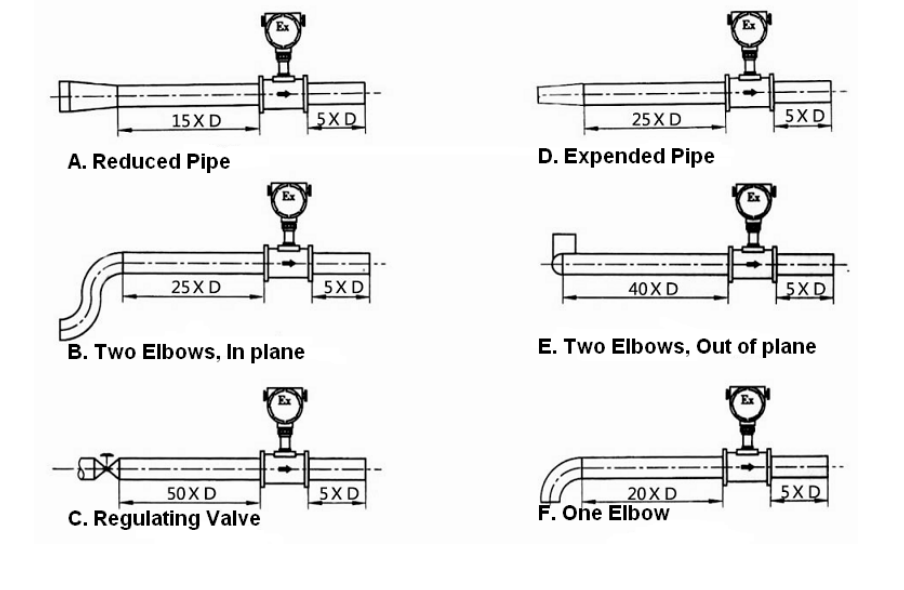

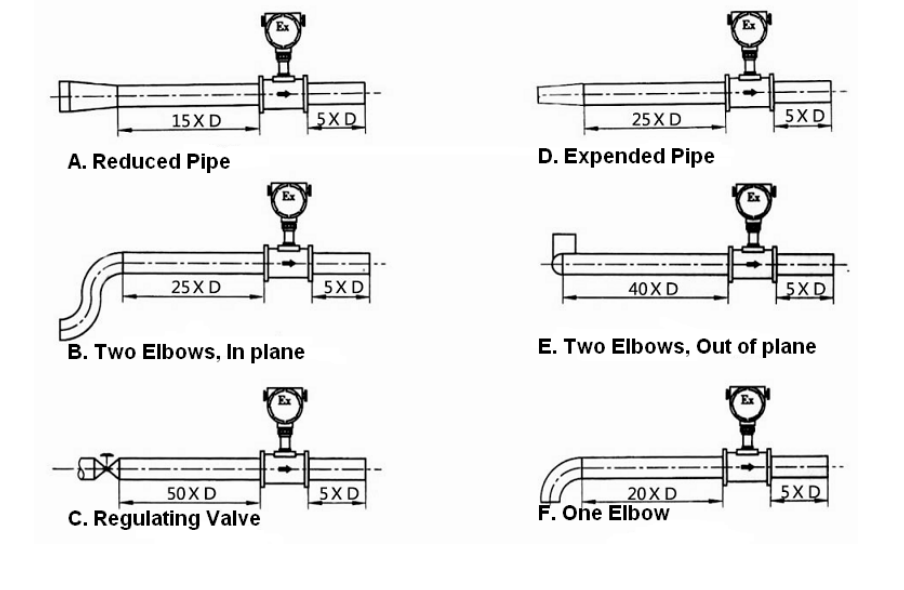

The flow go though the pipeline is hard to predit and when volume of steam way to small might out of the min measurement range of that meter most on the market is 4 or 6ms and vice versa. If there are two or more flow resistance parts at upstream of flowmeter the straight pipe should be much longer.

Vortex Flow Meter Installation Guide

The force generated by the vortex pressure pulse is a function of fluid density multiplied by the square of fluid velocity.

. The desired upstream straight pipe length is 1000mm. If the indicated straight run is not available Consult Factory. For example with the 50mm pipe there should be 500mm of straight pipe immediately upstream.

Traditional orifice plates for dP measurements can require up to 44-inch pipe diameters straight run of pipe upstream and 7 downstream before the measurement across the plate should be made. Turbine flowmeter piping requirements. Elbows reducers etc upstream of the sensor will distort the flow.

The required straight run is depeding on the type of flowmeter. A 2 in. This allows the output of the vortex meter to be adjusted for the actual process temperature and process piping being used.

I know there are some requirements on the straight pipe length before a vortex air flowmeter so that accuracy of the flowmeter will not be adversely affected. Usually 20x to 50X upstream straight run requirement recommended. The requirement that there be turbulent flow and force sufficient to actuate the sensor determines the meters rangeability.

Vortex flowmeters are used in numerous branches of industry to measure the volume flow of liquids gases and steam. Vortex meters operate on the principles of the Von Kármán effect which describes how a vortex is created behind a bluff body when fluid passes by it. For example a 90-degree bend before the flowmeter the straight pipe length required before the flowmeter shall not be less than 10 x D D diameter of the.

The amount of straight run needed can depend on how many disturbances exist upstream especially when using a turbine style flow meter. The longest straight pipe should be used between flow resistance part and flowmeter. Next we will detail the various flow meters Upstream and.

Vortex Up 25 25 30 Down 5 5 5 Thermal Up 15 15 40 Down 5 5 5 Turbine Up 10 10 10 Down 5 5 5 Annubar Up 8 9 24 Down 3 3 4 Note. Meter would also do as it has a range of approximately 15 to 53 m³hr. Additional straight-pipe recommendations include.

The seals attach to the meter body immediately upstream and downstream of the restriction. Data is presented in this paper to demonstrate the effectiveness of the design in limiting the errors resulting from piping. The minimum Reynolds number is only 500 and the meter requires only five diameters of upstream straight pipe run.

Over or below the calibration range will. 20 pipe diameters for 90-degree elbow tee filter strainer or thermowell. They rely on vortex shedding and require a certain minimum flow velocity to generate the vortices the frequency is linearly related to the fluid velocity.

Vortex Flow Meter is an intelligent vortex meter providing a digital output signal that contains more information than just flow rate. Thus a vortex flow meter implement TP density compensation so can deliver accurate measurement result of steam. 25 pipe diameters for a.

However if you are using a conditioning orifice plate with a 4 beta straight run requirements range from 2-6 straight pipe diameters. Vortex flow meters like a fully developed flow profile and typically require long straight upstream piping runs. The general rule of thumb for straight piping is a five-diameter length of piping upstream and three diameters downstream from the meter measured from the center of the tube.

The recommended straight run by type is shown below. Longer upstream straight pipe lengths provide better accuracy. But a partially open valve upstream of the meter will require 25X the piping.

The microprocessor in the flowmeter can automatically correct for insufficient straight pipe conditions for differences between bore and mating pipe diameters for cliff body thermal expansion and for K-factor. Obtaining the necessary straight lengths can be difficult especially in compact plants. Saturated steam superheated steam compressed air nitrogen liquefied gases flue gases carbon.

Due to the nature of the measuring probe protruding into the media and creating its own obstacle of sorts the straight run requirements for insertion flow meters is high. They rarely require cleaning even in services like dewatered sludge black liquor coal slurry fly ash slurry taconite and crude oil. The length of straight pipe 15D for upstream and 5D for downstream if converging.

The straight runs shown above are conservative minimums. As a result of this testing compensation factors are included in the vortex meter software. What are the Straight Run Requirements for Insertion Flow Meters.

If you are compensating for pressure and temperature then allow 3 to 4 pipe diameters between the meter and. Typical manufacturer specifications for turbine meters call for straight-pipe lengths of 10-15 pipe diameters upstream and five diameters downstream. Vortex units are velocity meters.

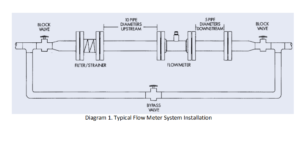

Ensure enough straight pipes at upper down stream. 15 rows To obtain specified accuracy straight run both for upstream and downstream is needed. Allow a minimum straight pipe length at least 10 times the internal diameter of the pipe.

Straight run should be at least 20x the piping diameter when an elbow tee filter or other disruption exists upstream of the meter. This force has to be high enough to be distinguishable from noise. Applications in the chemicals and petrochemicals industries for example in power generation and heat-supply systems involve widely differing fluids.

Allow a minimum straight pipe length at least 5 times the internal diameter of the pipe. Therefore it is worth remembering that Vortex meters can be installed vertically horizontally or at any angle as long as they are kept flooded.

Sizing And Installing Vortex Meters

Vortex Flow Meter Upstream And Downstream Requirements Just Measure It

Vortex Flow Meter Straight Piping Line Requirements

Vortex Flow Meter Straight Piping Line Requirements

Vortex Flow Meter Upstream And Downstream Requirements Just Measure It

Vortex Flow Meter Installation Guide

0 comments

Post a Comment